How to easily winterise your garden pump

Before the temperatures drop permanently, it is worth taking a closer look at the pump technology installed outdoors. Many owners ask themselves whether water-bearing components should generally be drained or whether certain models require a special procedure. Basically, this depends on the frost-free positioning and the design, which is why a careful check is crucial to ensure safe operation in spring.

In order to winterise a garden pump, it is particularly important to completely remove any residual water from the pipes, pump housing and suction nozzle. Frost leads to expansion even with a small amount of liquid, which can cause fine hairline cracks or serious damage to the housing. It is therefore advisable to switch off the system early, drain it properly and then store it in a dry place. Many models can be opened in a few simple steps, which makes draining easy and protects the pump permanently.

You should also clean the hoses and filter inserts thoroughly. Deposits and residues can harden over the winter and lead to a loss of performance during subsequent operation. Careful cleaning ensures that your technology starts without delay the next time it is used and that the maximum flow rate is achieved. If you also check all seals, you can recognise potential leaks at an early stage and rectify them before the start of the new season.

Summary

- Disconnect from the power supply

- Drain the water completely

- Disconnect or remove hoses if necessary

- Clean the pump

- Check and maintain seals

- Store the pump in a frost-free, raised and dry place

Types of cistern and garden pumps and their special features

The AspriPlus suction and pressure pump works above ground and is particularly suitable for installations where rainwater needs to be reliably drawn from a cistern or tank and transferred at a constant pressure. It is characterised by a robust design that enables stable pumping.

The Multigo submersible pressure pump is operated directly in the water and, with its compact design, delivers a high pumping capacity even from greater depths or distances. It is optimised for use in cisterns and remains particularly quiet thanks to its positioning in the water. As it is fully submerged, it is generally suitable for winter operation at frost-free depths. It can remain in use in the cistern as long as the pressure hoses are also protected from frost.

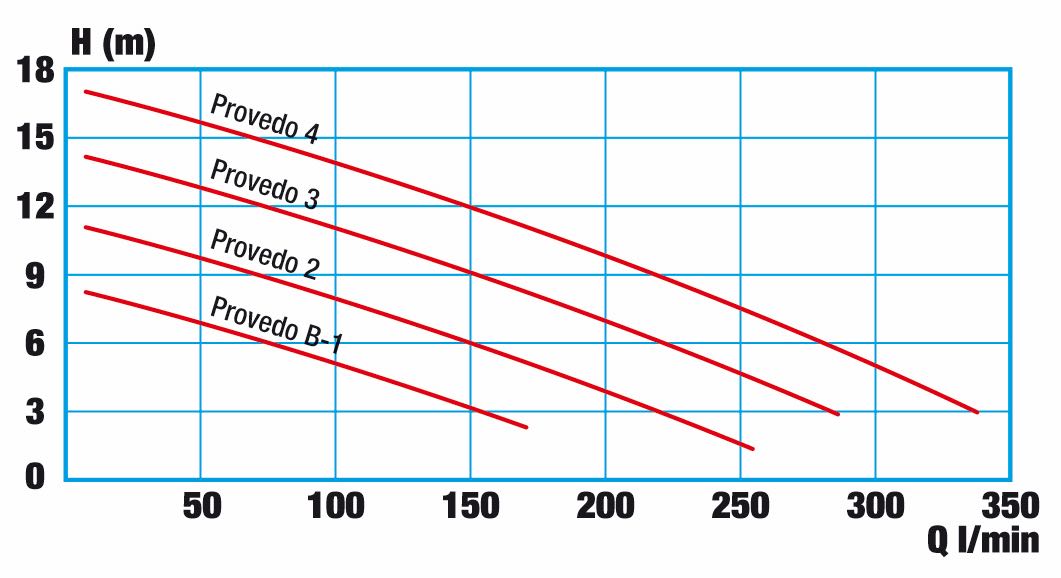

The Provedo submersible feed pump is suitable for demanding applications where a constant supply from rainwater cisterns is required. Installation below the frost line means that the pump remains well protected, which supports long-term operation and at the same time ensures a stable supply.

The Beta submersible garden pump is designed for typical garden applications. With its integrated control system, it impresses with its reliable pumping of rainwater. It can be flexibly integrated into existing systems, allowing different irrigation concepts to be realised. As it sits in the water, it benefits from the insulating effect of the cistern, which protects the sensitive components from extreme outside temperatures and ensures operational reliability even in cold months.

How to prepare the garden pump for winter

Thorough preparation will ensure that your technology survives the cold season without damage. Once all the pipes have been drained, it is advisable to remove the pump from the system and store it in a well-ventilated place to maintain its functionality.

If the system is located in an area where frost normally does not occur or only occurs for a very short time, it can also be protected by suitable insulation and a weatherproof cover if it is to remain in its installation location. Even in this case, however, the water should be drained from the system. Sections that are particularly susceptible to frost, such as pipes laid above ground, benefit from high-quality insulation that cushions temperature fluctuations and reduces material wear. The combination of cover and insulation serves as a preventive protective layer that noticeably reduces the load on the entire conveyor system.

You will need various tools for the preparatory work, such as

- a suitable spanner for the drain plug and hose connections

- a bucket for collecting residual water

- a soft cloth for cleaning and insulating materials

- a robust cover

If you have these tools to hand, you can carry out all the necessary steps efficiently and avoid interruptions.

When do I need to dismantle the garden pump?

Ideally, the pump should be dismantled or winterised between October and mid-November. This allows the pump to be emptied in good time and prevents damage caused by unexpected frost, which can occur early in the year.

Before final storage, it is worth carefully cleaning all components and checking for visible damage. Limescale deposits, dirt particles and small sealing faults can often be rectified directly once the pump has been dismantled. Drying all components prevents corrosion and ensures that the technology retains its performance in the long term as soon as it is put back into operation.

Step-by-step instructions

1. Step: Disconnect from the power supply

To winterise a garden pump, the process always begins with safe disconnection from the power supply before carefully dismantling the system. As soon as all connections have been loosened, you can dismantle the garden pump in winter and remove it from the system in a controlled manner so that no residual water remains inside.

Step 2: Drain and disconnect the delivery lines

Once the pump has been removed, all delivery pipes should be completely drained and disconnected to prevent any liquid from building up that could expand in the cold. This process helps to protect a water pump from frost, as external pipes are particularly sensitive to sub-zero temperatures. If you take care to check all sections carefully, you will significantly minimise the risk of material cracks and leaks.

Step 3: Cleaning the pump

In the next step, it is worth thoroughly cleaning the pump to remove dirt particles and deposits in order to ensure its functionality for the coming season. At the same time, visible damage can be recognised and repaired in good time before the technology is put into storage. A clean and inspected system extends the service life and ensures that operation can start without delay in the spring.

Step 4: Frost-proof storage

To complete dismantling, the pump is stored in a frost-proof location that is dry and well ventilated so that no moisture can penetrate. A raised storage surface also prevents contact with cold floors and protects the components in the long term. If you comply with these conditions, you will create optimum conditions for reliable recommissioning after the winter break.

Alternative

Alternatively, technology that has been completely drained of water can be winterised without dismantling, provided that high-quality insulation and a suitable cover are in place. This combination reduces temperature differences and protects sensitive areas from the cold.

Troubleshooting and maintenance in spring

At the end of the cold months, it is advisable to check the entire system carefully before putting the garden pump back into operation. This includes a visual inspection of all connections, checking the seals and cleaning the intake and delivery areas to ensure that dirt residues from winter storage do not affect performance. A brief function test without load shows whether the impeller is working freely and the electronics are responding correctly.

Various problems can occur in spring, which are often caused by residues, leaks or worn components. Loss of performance due to clogged filters can usually be remedied by thorough cleaning, while air in the pipes prevents suction and can be solved by refilling the system. Dripping points on connections often indicate porous seals, which can be replaced in a few simple steps and then enable a stable delivery pressure again. Checking all components at an early stage can increase operational safety and ensure a reliable water supply for the entire season.